Standard Product Range

Chosen by engineers for engineers

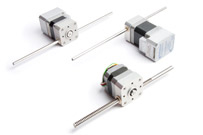

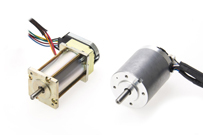

Rotary Motion, Linear Motion, Intelligent Control and Actuation

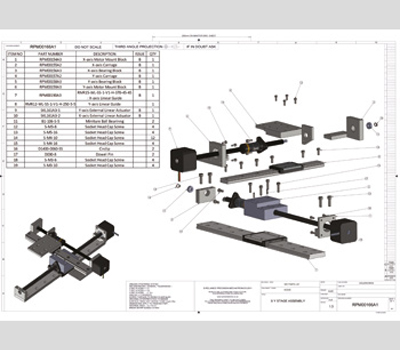

Reliance’s standard product range of motion control solutions is defined in our catalogue. Each product is offered with a refined, considered range of options and associated products, even circlips and screws, all of which have been engineered to interface correctly. If you are not sure whether we offer the specification you need for any of our products then please contact us.

Our product range can be readily modified to support your application. We can combine standard and modified products to provide cost-effective sub-systems and assemblies as well as offering fully bespoke, integrated solutions.

Helping You Make an Informed Choice

Wherever possible we like to build a thorough understanding of your application and wider system design (including the technical, operational and commercial requirements) so that we can confidently recommend the most appropriate standard product, modified product or integrated solution.

Our aim is to help you make an informed choice about our products before you make a purchasing decision; we want to be confident that what we deliver is going to work for you.

Test and Manufacturing Expertise

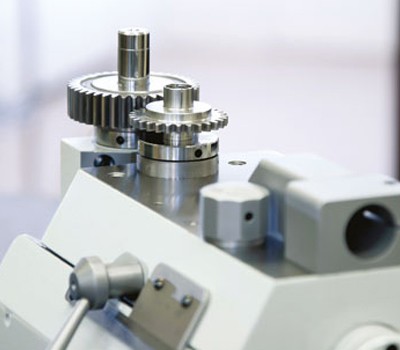

Our design engineering knowledge is underpinned by sustained investment in test development facilities. Our extensive test data allows us to offer in-depth understanding of the capabilities of our standard product range.

Our manufacturing capability also helps provide insight into the fitness-for-purpose of the products, based on an understanding of the manufacturing methods used, quality control, surface finish, accuracies and other key criteria which ultimately impact on the performance of your products.

Established in Diverse, Global Markets

In Switzerland our tubular round racks provide a space-saving solution for laboratory automation, locating fluid tubes and fibre optic cables inside the rack to give a more compact instrument.

In Asia our precision anti-backlash gears are used in military applications where our innovative, two-piece gear design is ideal for high reliability applications.

In the UK over 5,000 syringe drive mechanisms, using our motors and lead screws, are in operation in drug dispensing systems.

In the Netherlands our vacuum compliant actuators are used in electro-beam microscopes.

In Switzerland, France and Germany our spline shafts and lead screws are used in liquid handling systems.